Cemento poroso a base di silice derivato da rifiuti per la cattura, lo stoccaggio e il riutilizzo dell'anidride carbonica (SILCO).

La CO2 è uno dei responsabili per il cambiamento climatico, e vengono fatti sforzi per sviluppare sistemi efficienti ed economicamente vantaggiosi per catturarla, conservarla e riutilizzarla.

Il progetto SILCO è stato ideato e pianificato per rispondere a tre obiettivi del PNRR dell'UE e dell'Italia: il cambiamento climatico, proponendo nuovi materiali per la cattura e l'utilizzo della CO2 (SDG13 - azione per il clima); l'energia accessibile, proponendo la trasformazione della CO2 in idrocarburi (SDG7 - energia accessibile e pulita), e il consumo responsabile delle risorse, proponendo lo sviluppo e l'applicazione di matrici di silice derivate da rifiuti (SDG12 - consumo e produzione sostenibili), con particolare attenzione alla circolarità dell'approccio proposto.

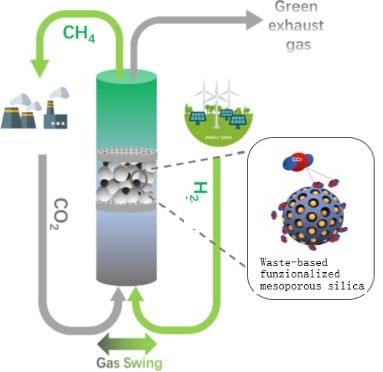

Si prevede lo sviluppo di matrici sorbenti derivate da rifiuti (WSM) a base di silice e/o silice modificata con specifica funzionalizzazione e porosità, adatte per la cattura e lo stoccaggio di CO2 ad alta efficienza e per l'utilizzo come catalizzatori di supporto per la produzione di combustibili ad alta resa e selettivi.

Altri aspetti importanti di SILCO riguardano lo studio e la messa a punto di metodologie per la caratterizzazione e la valutazione del rapporto struttura-prestazioni dei sorbenti e dei catalizzatori. Il concetto innovativo di SILCO si basa sulla messa a punto di metodologie in grado di consentire una gestione efficiente dei rifiuti, compresa la CO2, per reintrodurli nel ciclo produttivo dando loro nuova vita e valore.

Tra gli altri, gli output applicativi di SILCO possono essere:

- l'applicazione di nuovi WSM, attualmente non disponibili sul mercato, nelle tecnologie attuali, e

- la possibilità di implementare nuove tecnologie, che si occupano di processi di riciclaggio, ancora non applicate a livello industriale.

L'ambiziosa visione a lungo termine di SILCO può essere fondamentale per nuove tecnologie in grado di generare importanti opportunità di lavoro. Le implicazioni ambientali del riutilizzo e del riciclo dei residui di silice sono positive per quanto riguarda le materie prime, le risorse, i costi e la riduzione delle discariche. Effetti positivi ancora più impattanti si avranno considerando il recupero e la valorizzazione della CO2 . Il riscaldamento globale è considerato una delle sfide più importanti del XXI secolo, così come la cattura della CO2 ; pertanto, le tecnologie di stoccaggio stanno suscitando grande interesse per ridurre la quantità sempre crescente di CO2 rilasciata nell'atmosfera e il suo impatto sul cambiamento climatico globale. Lo sviluppo di un catalizzatore robusto per la riduzione selettiva della CO2 direttamente in combustibili idrocarburici è molto impegnativo sia dal punto di vista energetico che ambientale, poiché offre una via rinnovabile e verde per la produzione di combustibili. La produzione di gas naturale sintetico dalla CO2 mediante una reazione di metanazione è quindi una promettente tecnologia di cattura e utilizzo del carbonio che porta al suo riciclo.

Silici mesoporose a base di rifiuti (MS)

Le silici mesoporose (MS) hanno attirato grande attenzione come materiali sorbenti grazie alle loro caratteristiche eccezionali, ovvero strutture ordinate dei pori, elevata area superficiale e un'ampia scelta di morfologie (polveri, dischi, aste e sfere, ecc.). Rispetto alla silice porosa convenzionale, gli MS mostrano pori estremamente ordinati, grazie al metodo di nano-templatura applicato nella loro sintesi. Le superfici degli MS, contenenti gruppi silanolo, sono i fattori chiave per le loro prestazioni, che possono essere ulteriormente migliorate tramite la funzionalizzazione con diverse molecole.

Recentemente, l'acido esafluorosilicico di scarto industriale H2SiF6 (FSA) si è dimostrato un'alternativa a basso costo per la sintesi di materiali silicei, attualmente in fase di test di produzione in impianti pilota, e la silice mesoporosa ottenuta da FSA ha confermato la sua idoneità come supporto sorbente attraverso la modifica della superficie, mostrando prestazioni paragonabili a quelle di materiali simili preparati da precursori convenzionali.Le superfici di MS, contenenti gruppi silanolo, sono i fattori chiave per le loro prestazioni, che possono essere ulteriormente migliorate attraverso la funzionalizzazione con diverse molecole.

Le interazioni CO2-materiali di superficie variano da materiale a materiale, a causa della natura delle molecole funzionalizzanti. Inoltre, la funzionalizzazione della superficie con gruppi funzionali adeguati può aumentare l'affinità delle interazioni tra CO2 e silice. La CO2 catturata può essere immagazzinata o ulteriormente convertita per generare prodotti a valore aggiunto (ad esempio, prodotti chimici e combustibili), secondo il concetto di cattura e utilizzo del carbonio (CCU). Questa tecnologia, che prevede la conversione degli scarti di CO2 in prodotti a valore aggiunto utilizzando energia rinnovabile, dovrebbe avere un forte impatto nella mitigazione dei cambiamenti climatici.

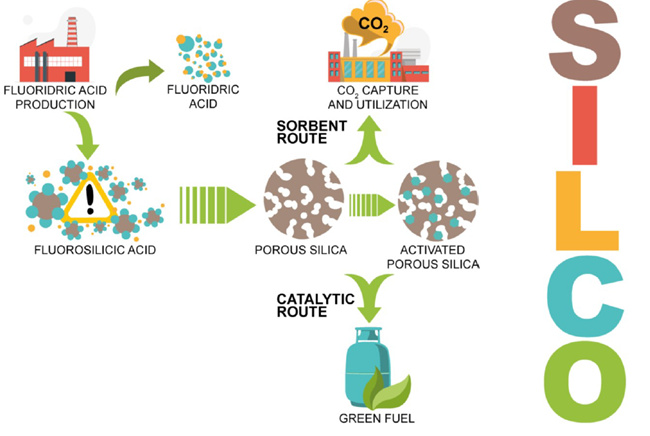

La rappresentazione grafica dell'idea di base di SILCO è schematizzata nella figura seguente:

SILCO ha proposto la produzione di silice con caratteristiche morfologiche, strutturali e di porosità ben definite, come materia prima secondaria dal recupero e dal riutilizzo dell'acido esafluorosilicico (FSA), adatto al recupero dei gas e alle applicazioni catalitiche, obiettivi del progetto. L'FSA è un sottoprodotto pericoloso della produzione di fluoruro di alluminio e di acido fluoridrico e delle industrie di fertilizzanti nell'area del Mediterraneo (Nord Africa e Vicino Medio Oriente) con applicazioni limitate, tra cui la produzione di fluoruro di alluminio a bassa densità e la fluorizzazione dell'acqua potabile e, dove questa pratica è legale (non nell'UE), viene principalmente smaltito in mare dopo la neutralizzazione. Il progetto SILCO mira a integrare una soluzione tecnologica innovativa e sostenibile a rifiuti zero per utilizzare l'FSA per produrre fluorite (CaF2), materia prima critica solida e non pericolosa per l'industria del fluoro, e silice precipitata (HD-SiO2), nel pieno rispetto dei principi della chimica verde e dell'economia circolare. Si basa sul processo di amminazione FSA brevettato da Fluorsid per il recupero della fluorite. L'integrazione riguarda la modifica del processo di recupero della silice per produrre nanoparticelle di SiO2 morfologicamente controllate con dimensioni, area superficiale e porosità definite per applicazioni quali il recupero della CO2 e i catalizzatori per la produzione di metanolo dalla CO2.

Ciò potrebbe offrire prospettive molto più interessanti per il riutilizzo della controparte silicea dell'FSA, valorizzando il processo di recupero della fluorite e migliorando ulteriormente l'ecosostenibilità del processo. La transizione verso sistemi di produzione e consumo più circolari avrà inevitabilmente un impatto sia sul numero di persone impiegate nel settore, sia sulle loro competenze.

Le attività sperimentali del SILCO sono volte a dimostrare la possibilità di sviluppare e utilizzare silice derivata da rifiuti e/o ossido di silice modificato con specifica funzionalizzazione e porosità, adatto per la cattura e lo stoccaggio di CO2 ad alta efficienza e, dopo la funzionalizzazione, come catalizzatore per la produzione di metano ad alta resa e selettivo. Inoltre, è previsto lo studio e la messa a punto di metodologie per la caratterizzazione e la valutazione del rapporto struttura-prestazioni.

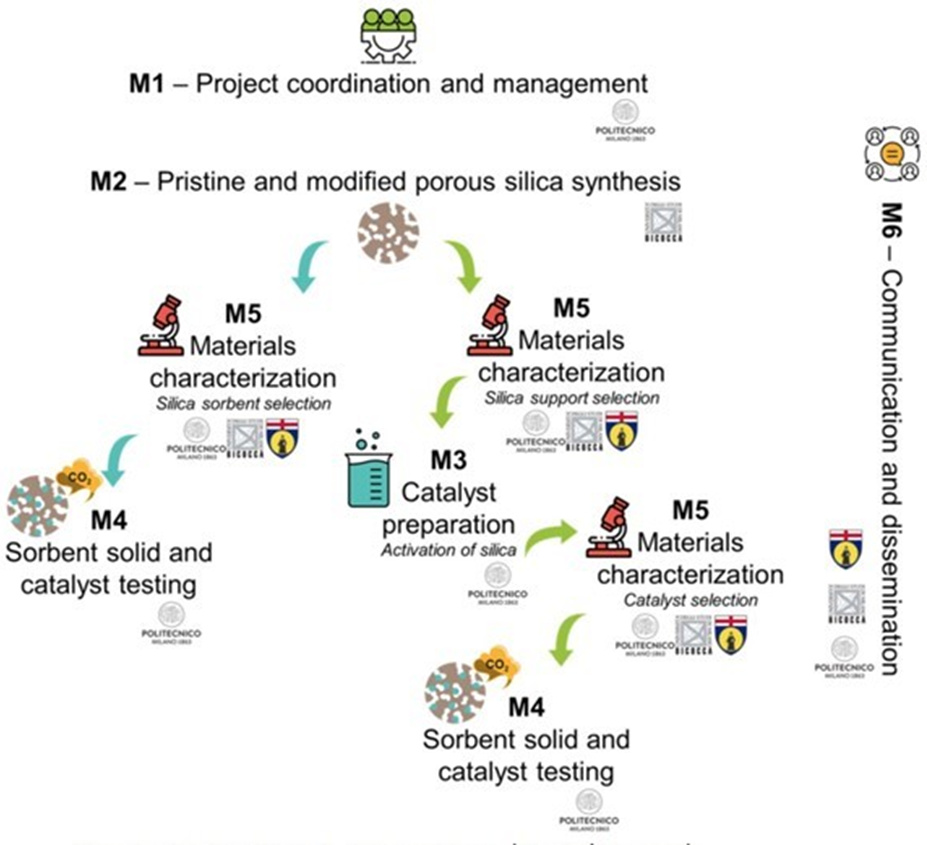

Il piano di comunicazione e scambio di informazioni all'interno del progetto e tra le quarte unità di ricerca coinvolte nel progetto sarà realizzato secondo il diagramma di flusso riportato nel diagramma di Pert del progetto: